TECHNOLOGY

How Industrial Materials Brokers Facilitate Efficient Supply Chain Management

In an era where global supply chains are increasingly complex and constantly under pressure, the ability to secure essential materials quickly and cost-effectively has become a defining factor in operational success. From aerospace to construction, companies are navigating volatile markets, shifting regulations, and tight production timelines. As traditional procurement methods struggle to keep pace, a new type of intermediary has emerged: the industrial materials broker.

The Role of Industrial Materials Brokers in Modern Supply Chains

The relentless need for speed, flexibility, and cost control defines today’s industrial landscape. Manufacturers, construction firms, and project managers face continuous pressures to deliver more with less, and the stakes attached to efficient supply chain management have never been higher. This is where an industrial materials broker can make a pivotal difference. Rather than serving as ordinary middlemen, these experts act as highly skilled connectors and problem-solvers, facilitating the movement of essential raw materials and finished components between a vast network of global suppliers and buyers. Their nuanced market understanding provides procurement teams with crucial access to information, negotiation leverage, and a broader supplier base, ensuring greater agility in the face of disruptions or sudden demand spikes.

The value of an industrial materials broker extends well beyond sourcing. These professionals monitor domestic and international market trends, identify potential bottlenecks in the logistics chain, and proactively recommend purchasing strategies designed to minimize risk and optimize supply chain efficiency. In fast-moving industries—such as aerospace, automotive, and energy—it’s not uncommon for material prices to fluctuate drastically within days or weeks. Brokers provide real-time insight into these shifts, helping companies hedge against volatility and preserve profit margins. Ultimately, organizations that foster strong partnerships with brokers find themselves better positioned to respond to unforeseen events, secure crucial materials, and consistently hit their production targets.

Connecting Buyers and Sellers at Scale

The real power of an industrial materials broker lies in its ability to bridge the gap between highly specialized buyers and a sprawling, often fragmented, supplier landscape. Most brokers maintain extensive networks, comprising hundreds or even thousands of vetted suppliers that span multiple continents, industries, and material types. From raw materials procurement, such as securing base metals, specialty chemicals, or composite resins, to sourcing a rare alloy for aerospace manufacturing or locating a specific batch of high-grade polymers for medical devices, brokers have the market reach to move quickly, negotiate on behalf of buyers, and confirm supplier legitimacy.

- Rapid Sourcing: When a standard distributor faces a backlog or receives an out-of-stock notice, brokers can tap into their extended network, often securing materials within days that might otherwise take weeks to find.

- Price Negotiation: Due to their collective purchasing power and long-term supplier relationships, brokers often secure better pricing and more flexible contract terms than individual buyers can achieve independently.

- Specialty Materials: The broker’s broad reach and industry experience make it feasible to locate niche or highly regulated materials that aren’t typically available through standard distribution channels.

For example, a mid-sized manufacturer may partner with a broker during a global steel shortage. While most competitors compete for limited stock, the broker’s relationships allow them to source alternative grades or new suppliers, resolving shortages in a fraction of the time. Additionally, brokers can arrange testing or validation when alternative materials are proposed, ensuring compliance without sacrificing quality.

Benefits of Working With an Industrial Materials Broker

Partnering with a skilled broker brings several distinct advantages to organizations looking for a more robust, efficient supply chain:

- Market Intelligence and Forecasting: With real-time access to commodity pricing, lead times, and production forecasts, brokers provide buyers with the data they need to make informed purchasing decisions, secure favorable terms, and mitigate the impact of price spikes.

- Risk Reduction: By suggesting backup suppliers, alternative sourcing routes, or substitute products, brokers help companies avoid costly delays, unplanned downtime, and missed delivery targets.

- Operational Efficiency: Brokers streamline complex order management, handle cross-border regulations, and manage transportation logistics—freeing up time and resources for core business activities.

- Inventory Optimization: With data-driven recommendations, brokers help avoid both material shortages and surplus stock, supporting lean operational practices and freeing up working capital.

These benefits translate directly to financial savings through more competitive bids, improved on-time delivery rates, and reduced carrying costs. The right broker can also be a valuable sounding board for inventory strategies, engineering changes, or sustainability initiatives.

The Impact of Technology on Materials Brokering

In recent years, digital transformation has reshaped the materials brokering landscape. Modern brokers harness inventory software, online order management platforms, and data analytics to drive visibility, speed, and trust within the supply chain. Additionally, artificial intelligence and big data analytics empower brokers to anticipate market trends before they become obvious risks to clients, such as forecasting raw material shortages, price surges, or geopolitical disruptions. For buyers, technology-enabled brokers offer dashboards for on-demand tracking and customized reporting, enabling them to manage inventory levels, review vendor performance, and plan for seasonal fluctuations with unprecedented accuracy. Through transparent and data-driven communication, both parties can respond more quickly to issues and capitalize on new opportunities.

Choosing the Right Broker: Key Considerations

Selecting an effective industrial materials broker is a key step in building a resilient supply chain. While experience and supplier network size matter, organizations should also consider the broker’s reputation for transparent pricing, flexible contract terms, and willingness to integrate with digital procurement platforms. As highlighted in this Investopedia article, choosing a broker isn’t just about finding someone with connections—it’s about selecting a partner who offers reliability, clear communication, and aligns with your long-term goals. A reputable broker will eagerly offer client testimonials, share case studies, or provide industry certifications demonstrating consistent performance.

- Industry Expertise: Ensure the broker has a proven track record in your industry or material class.

- Supplier Diversity: A broader supplier base offers more flexibility in times of disruption.

- Open Communication: Reliable brokers excel in proactive, clear, and frequent updates, especially when problems or opportunities arise.

- Technological Integration: Brokers utilizing state-of-the-art digital tools facilitate seamless collaboration and enhanced reporting.

- Problem-Solving Attitude: The best brokers are solution-focused, creative, and responsive in times of crisis or when urgent needs arise.

Regularly reviewing supplier and broker performance can help companies continually optimize their approach as organizational needs or markets change. Selecting the right broker partnership often means a faster recovery from setbacks and a stronger competitive position.

The Future of Industrial Supply Chain Management

With globalization, automation, and unpredictable market cycles, the demands on supply chain professionals will only intensify. As the Fourth Industrial Revolution reshapes industries through innovative technologies and digital integration, the need for agile, data-driven decision-making becomes paramount. According to Forbes, businesses must embrace technological evolution to stay competitive, making specialized partnerships more critical than ever. In this context, relying on the expertise and insights of industrial materials brokers is set to become an essential best practice rather than a luxury. Organizations that seek out brokers versed in both the nuances of global trade and the latest technology solutions will tap into deeper supplier pools, negotiate better terms, and consistently deliver on customer expectations. In a world where availability and speed are key differentiators, these relationships promise to be invaluable assets for a more resilient and efficient future.

TECHNOLOGY

Ensuring Workplace Safety: The Critical Role of Proof Load Testing

Understanding Proof Load Testing

Maintaining a safe working environment is not just about creating policies; it is also about following through with essential safety procedures. In industries such as construction, shipping, and manufacturing, lifting equipment is the backbone of operations. The failure of a lifting device can cause catastrophic injuries and significant financial losses. That is why proof load testing is regarded as a foundational aspect of safety management.

Proof load testing involves applying a controlled load, often exceeding the equipment’s rated capacity, to verify its ability to perform safely under stress. This proactive initiative is designed to catch structural weaknesses or fatigue before equipment is put to regular use. For those interested in regional solutions, proof testing Houston, TX, can help ensure your lifting devices meet the required standards.

During proof load testing, certified professionals use specialized tools to simulate real-world loading conditions. This thorough approach is not just about equipment validation; it also serves as a critical safeguard for workers and reduces the likelihood of operational downtime due to unexpected equipment malfunctions.

According to guidelines established by the Occupational Safety and Health Administration (OSHA), this kind of safety testing is both a best practice and a regulatory requirement for many types of lifting machinery.

Equipment Requiring Proof Load Testing

Various types of lifting equipment, both large and small, require regular proof load testing. Among the most critical are:

- Overhead and gantry cranes

- Hoists and winches

- All forms of lifting slings, including wire rope, chain, and synthetic options

- Shackles, hooks, lifting beams, and other critical rigging hardware

The failure of any of these components during use can result in dropped loads, injuries, or fatalities. This necessity makes routine inspection and proof-load verification a non-negotiable part of maintenance schedules.

Frequency and Triggers for Testing

When should proof load testing be conducted? Safety experts and industry regulations point to several key triggers:

- Before the initial use of new equipment

- After any significant modifications or repairs

- As part of scheduled, periodic reviews, frequency often depends on usage cycles and environmental conditions

OSHA guidelines mandate that custom lifting devices be tested to 125 percent of their rated load before being put into service. These proactive steps are essential for both brand-new equipment and older devices that have seen repairs or heavy use.

Consequences of Neglecting Proof Load Testing

Failing to perform scheduled or required proof load tests can have serious repercussions. The obvious impact is the increased risk of workplace accidents and injuries when equipment fails unexpectedly. Companies can also be left vulnerable to:

- Costly legal actions and OSHA fines for non-compliance

- Significant damage to reputation that affects both employee morale and client relationships

- Permanently tarnished business credibility due to well-publicized safety failures

Work-related fatalities or severe injuries due to preventable equipment failures are catastrophic for everyone involved. The direct and indirect costs of insurance increases and litigation, as well as workforce disruption, can cripple organizations that do not make safety testing a regular priority.

Best Practices for Conducting Proof Load Tests

To maximize the value and reliability of proof load testing, experts recommend several best practices. These include enlisting certified testing professionals familiar with current OSHA and ASME requirements, using well-maintained, calibrated equipment, and maintaining detailed documentation of all results. Regularly reviewing and updating testing protocols ensures your organization keeps pace with technological advances and regulatory changes.

Training personnel on current test methods and maintaining detailed records are just as vital as the tests themselves. These records can be essential for audits, legal matters, and ongoing risk assessments. For continued industry insight and news, reputable sources such as Safety+Health Magazine provide extensive coverage on industrial safety developments.

Final Thoughts

Proof load testing is a non-negotiable pillar of workplace safety for organizations utilizing cranes, slings, hoists, and related equipment. It provides unequivocal evidence of an equipment’s safety and fitness for use, helping to prevent workplace injuries, avoid non-compliance fines, and foster a robust safety culture. The small investment of time and resources in regular proof load testing is far outweighed by the benefit of accident prevention, compliance, and operational peace of mind.

TECHNOLOGY

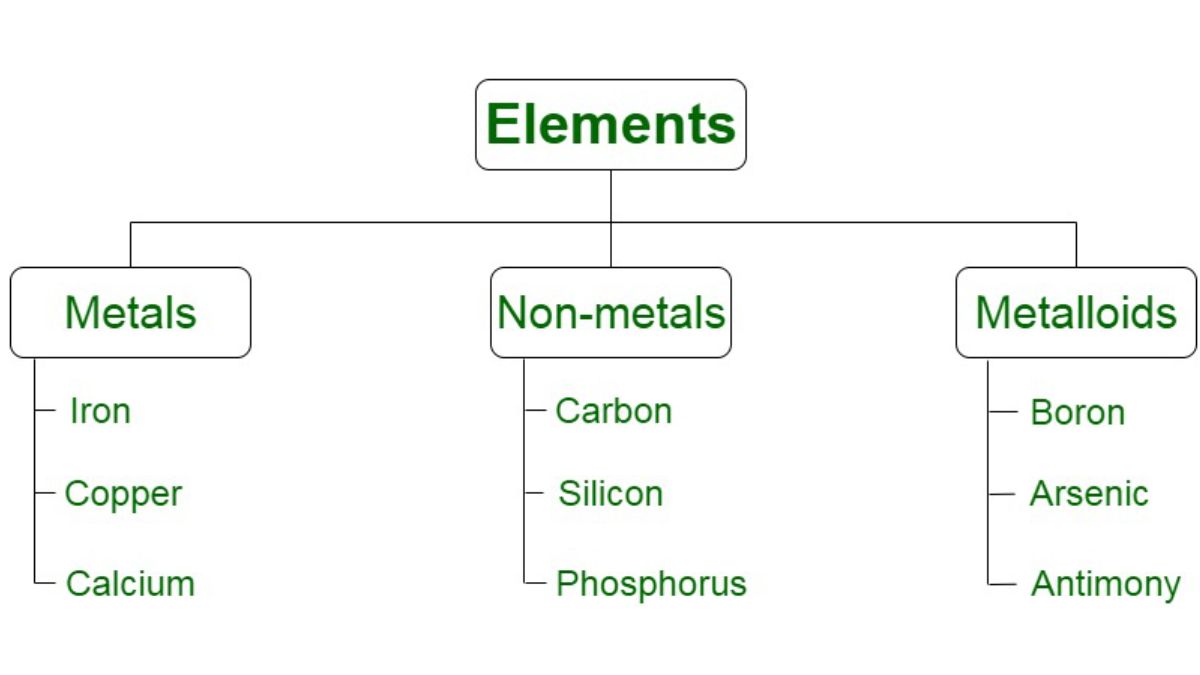

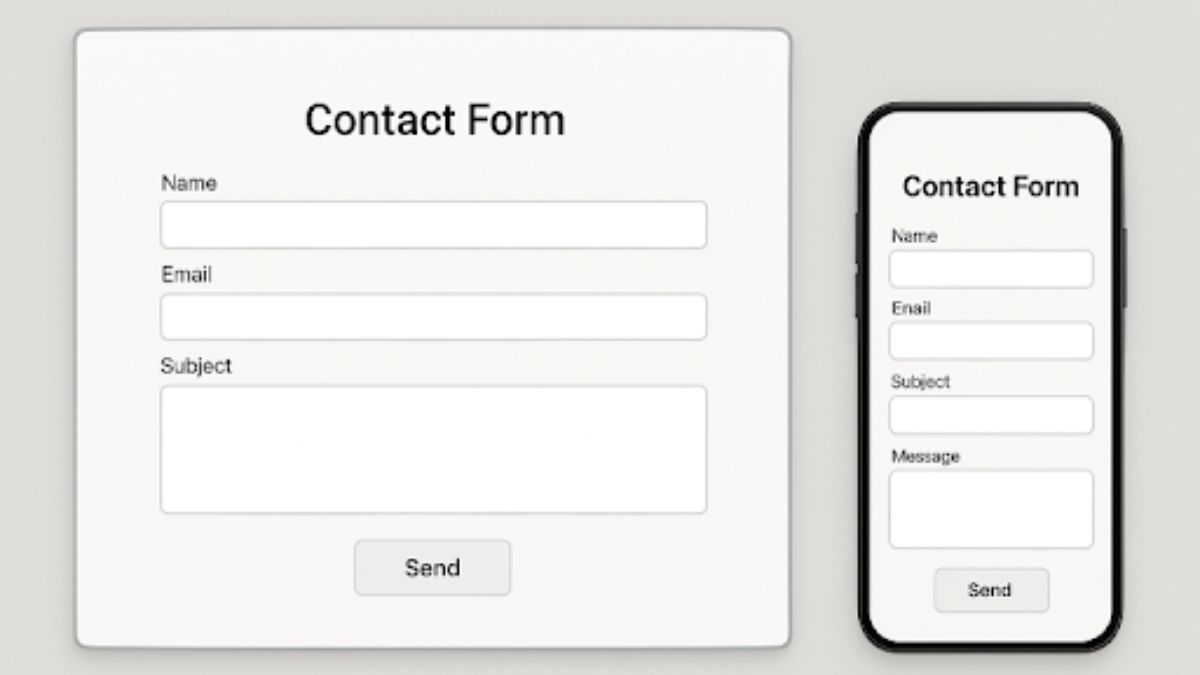

Essential Elements Every Contact Form Should Have

Contact forms play a pivotal role in how businesses receive inquiries, answer questions, and engage with their customers. Whether you are running a small business website or a corporate portal, making your contact form inviting and functional helps ensure visitors feel comfortable reaching out. Effective forms streamline communication, improve user satisfaction, and support business growth. For anyone looking to optimize their website’s contact touchpoints including those interested in car maintenance Bellevue, WA incorporating the right elements is key.

While strong design and ease of use are critical, there is much more to consider. Accessibility, clarity, robust security measures, and search optimization all contribute to the success of a contact form. By carefully balancing these elements, businesses can ensure their contact forms drive meaningful engagement and provide a better user experience for everyone involved.

Welcome users, encourage interaction, and make contacting your business as seamless as possible. In this guide, you will find actionable strategies and best practices for building the perfect contact form, whether for an auto shop in Bellevue or any other industry seeking to improve customer communication and conversion rates. According to the Nielsen Norman Group, even the smallest tweaks to form design can make a noticeable impact on your business’s ability to generate leads and answer customer inquiries.

Keep It Simple: Limit Fields to Essentials

Users are far more likely to fill out a contact form that asks only for essential information. Overly complicated forms with too many required fields tend to discourage visitors. Instead, focus on gathering the necessary data to act on customer requests. Typically, this means asking for:

- Name

- Email Address

- Subject or Inquiry Type

- Message

User fatigue can occur when forms feel laborious to use. By sticking to the basics, you show respect for a visitor’s time and increase the likelihood of receiving completed forms. This simple approach aligns with findings from major UX studies published by the Nielsen Norman Group, which show that shorter forms outperform longer ones in terms of submission rates and user satisfaction.

Ensure Accessibility and Mobile Responsiveness

It is crucial that every contact form is accessible across devices and to users of all abilities. With mobile traffic now accounting for the largest share of internet use, ensuring mobile responsiveness should be a top priority. This includes designing forms that automatically resize for smaller screens and remain easy to use on smartphones and tablets.

- Design with flexible layouts for different screen sizes

- Label all fields clearly for assistive technologies like screen readers

- Use placeholder text and error prompts that provide meaningful instructions

Accessibility is not just a best practice for compliance, but also expands your reach to all potential customers, including those with disabilities or who rely on technology to interact with your site.

Use Clear and Conversational Field Labels

Confusing or technical language can frustrate users. Field labels should be simple, familiar, and conversational. Instead of using internal terms such as “User Identifier” or ambiguous labels like “Details,” stick to what users expect. “Full Name,” “Your Email,” or “How can we help?” are examples that feel inviting and clear. This friendly approach reduces errors and increases the likelihood that users complete and submit your form.

Implement Strong Calls-to-Action (CTAs)

The submit button is an opportunity to boost conversion rates. Rather than settling for generic directives, make your calls to action clear and appealing. Personalized, enthusiastic CTAs like “Get in Touch with Us Today,” “Let’s Start a Conversation,” or “Request a Free Consultation” create urgency and excitement, encouraging users to reach out and connect.

Provide Feedback on Submission

Once a visitor sends their inquiry, displaying an automated confirmation message or sending a follow-up email is crucial. This feedback builds trust and reassures users that their submission was successful. It also sets expectations on how soon they might receive a response, reducing uncertainty and improving the overall user experience.

Display Alternative Contact Information

While many users enjoy the convenience of online forms, not everyone will feel comfortable using them. To ensure you are accessible to all preferences, include supplementary contact options prominently on your page. These can include your phone number, email address, live chat, or even social media links. Providing a range of alternatives improves trust and shows your commitment to open lines of communication.

Reduce Spam with CAPTCHA or Honeypots

Preventing spam is essential for maintaining a clean inbox and protecting your business from bots. Implementing a CAPTCHA, reCAPTCHA, or honeypot field is an effective way to block automated junk while keeping the form experience as easy as possible for real users. However, choose captcha solutions that balance effectiveness with usability to avoid frustrating legitimate visitors.

Optimize for SEO with Relevant Keywords

Contact forms can also improve your website’s search visibility when strategically optimized. Use clear, keyword-rich headers and meta descriptions, and ensure your form and surrounding content employ natural language that reflects your business and what you offer. Alt-text for icons or images, along with a logical, structured layout, further help search engines understand your page, potentially driving more organic traffic to your site.

Final Thoughts

With these essential elements in place, businesses can create forms that are not only attractive and functional but also capable of supporting high levels of user interaction, satisfaction, and conversion. These optimizations will help your contact page deliver real results and foster long-term relationships with your audience.

TECHNOLOGY

Safe and Practical Approaches to Old Oil Tank Removal

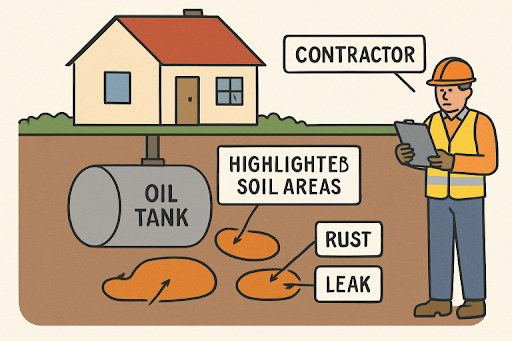

Old oil tanks, especially those installed decades ago, can pose significant safety and environmental risks to homeowners. Understanding how to safely manage the removal process prevents costly complications, legal issues, and health hazards. Homeowners should always prioritize best practices for safety, legal compliance, and environmental stewardship when considering oil tank removal. If you are searching for assistance, oil tank services Greenwood Lake, NY are available to provide guidance and hands-on help for these sensitive projects.

Identifying and removing out-of-date oil tanks is not only a matter of property maintenance but also an essential step in protecting groundwater, soil, and nearby inhabitants. Decommissioned or abandoned tanks can become liabilities for homeowners, especially if leaks go unnoticed. Professional removal ensures the proper handling of potential hazards and prevents structural damage, pest infestations, and future resale problems.

Homeowners should never attempt to remove tanks on their own. Trained professionals have the expertise, tools, and certification required to ensure the process is safe and compliant with state and federal regulations. Securing proper permits, hiring experienced contractors, and documenting every step help safeguard you from future remediation expenses or legal fines. When handled correctly, oil tank removal is a straightforward process that protects your home, your neighborhood, and the environment.

Understanding the Risks of Old Oil Tanks

Many residential oil tanks, particularly those placed before the 1980s, are vulnerable to rust, cracks, and leaks that allow oil to escape into the surrounding environment. Oil spills from neglected tanks can contaminate soil and groundwater, posing health risks and affecting drinking water quality. The costs of remediating an undetected leak can be staggering for homeowners. In addition to environmental threats, old tanks may attract rodents and insects or collapse, posing a risk of injury or property damage.

Identifying these risks early is the best defense against expensive restoration projects and liability claims. Homeowners are encouraged to check for signs of corrosion, leakage, or strong petroleum odors around their property. Even above-ground tanks are susceptible to these dangers after years of service and exposure to the elements.

Initial Assessment and Planning

Before beginning the removal process, a comprehensive assessment is mandatory. Licensed contractors can use advanced technologies such as ground-penetrating radar to locate underground tanks and determine their size, contents, and condition. This evaluation guides the creation of a safe removal plan, which forecasts the scope of work, required materials, costs, and potential challenges at your specific site.

A thorough inspection will also identify any pre-existing contamination or damage, which is crucial for planning effective remediation. Homeowners benefit from requesting a detailed written report from their contractor that documents the findings and outlines the proposed steps. Clear communication at this stage helps avoid misunderstandings or surprise expenses later. According to The New York Times’ homebuyer guide, assessing environmental risks is a vital aspect of property maintenance and transfer of ownership.

Obtaining Necessary Permits

Removing an oil tank is a regulated task in most states and municipalities. Obtaining the appropriate permits is crucial to ensure your project complies with local health, safety, and environmental codes. This typically involves submitting documentation, such as site diagrams and removal plans, to local or state agencies for review and approval. Notifications may also be required before excavation or site-disturbing activities. Complying with regulatory requirements can spare you costly fines and guarantee that the project is approved for future property sales or insurance purposes.

Engaging Professional Services

Professional assistance is a necessity when handling oil tank removal. Licensed contractors are certified to perform decommissioning, extraction, and transportation of hazardous materials in accordance with legal standards. They are equipped with proper safety gear and machinery for pumping out remaining fuel, cleaning tanks, and disposing of contents at regulated facilities. Choosing skilled contractors ensures due diligence and minimizes both health and legal risks. Always verify references, licensing, and insurance before signing a contract with a removal company.

Safe Removal Procedures

- Pumping any remaining oil from the tank and thoroughly cleaning the interior to eliminate flammable residues.

- Cutting open larger tanks, if needed, for safer extraction and easier handling.

- Excavating and lifting the tank from the ground with minimal disruption to landscaping and other utilities on the property.

- Monitoring for potential leaks or spills during every stage and preparing containment measures in advance.

Each step requires careful planning and strict adherence to safety protocols to protect the environment and ensure homeowner safety.

Soil Testing and Remediation

After an oil tank is removed, environmental specialists conduct comprehensive soil testing in the former tank area. This testing checks for trace contamination that may not be immediately visible. If pollution is found, remediation strategies might include soil excavation, chemical treatment, or bioremediation to restore the property’s safety and ecological health. Quick remediation limits ongoing legal risks and enhances property value.

Proper Disposal of Tank Materials

Old oil tanks and residual waste must be transported to approved disposal or recycling facilities in accordance with federal and state standards. Hazardous materials are processed to prevent environmental damage and ensure public safety. Contractors usually provide a manifest or a certificate of disposal that demonstrates compliance with waste management regulations. Improper disposal not only risks environmental damage but can also subject owners to severe legal penalties.

Site Restoration and Documentation

Once contaminated soil and the tank have been removed, the property should be restored to its original or improved condition. Contractors will backfill excavated areas and may recommend landscaping or erosion control as needed. Homeowners must retain all documentation, including permits, inspection reports, remediation summaries, disposal manifests, and related correspondence. These records serve as proof of compliance and are essential for future disclosures, refinancing, or sale of the property.

Final Thoughts

Adopting these safe and practical strategies for old oil tank removal shields homeowners from avoidable risk, preserves property value, and demonstrates environmental responsibility. Local professionals and national authorities provide valuable resources and expertise to support safe, legal, and efficient oil tank decommissioning.

-

Entertainment10 months ago

Entertainment10 months agoEnchantment & Excitement: Crafting Unforgettable Event Experiences

-

GENERAL1 year ago

GENERAL1 year agoFrom Fan Art to Original Works: The Diversity of doujindesu Creations

-

GENERAL11 months ago

GENERAL11 months agoEngland Business Visa Requirements for American and International Citizens in 2025: A Guide for Entrepreneurs

-

GENERAL10 months ago

GENERAL10 months agoCrossword Conundrum: The Significance of vault opener nyt crossword

-

GENERAL1 year ago

GENERAL1 year agoLatest Trends in Men’s and Women’s Jackets for the Upcoming Season

-

GENERAL10 months ago

GENERAL10 months agoExploring the World of nhentai.nef: A Comprehensive Guide for New Users

-

Health1 year ago

Health1 year agoDiscovering gel ooru: The Ultimate Guide to This Unique Traditional Craft

-

Entertainment10 months ago

Entertainment10 months agoExploring the World of NHentai: A Comprehensive Guide to nhentai.met